A catch pit is an empty chamber built into a drainage system to ‘catch’ silt and other debris carried along the drainage pipe by water.

Catch pits (sometimes spelt catchpits), silt traps or interceptor traps as they are also known – play a crucial role in preventing the build-up of material that can cause pipe blockages, resulting in backing up of water in the drainage system, which can result in localised flooding.

A catch pit and a soakaway should not be confused, with both serving very different purposes within a drainage system. A catch pit is designed to collect silt and debris before it enters any drainage system. Catch pits need regular maintenance to ensure optimum functionality. A soakaway drain is design to allow surface water to be collected and then the water to percolate back into the earth.

Catch pits are used in all wastewater management systems. This includes main line sewers and storm water drainage systems used to manage water along highways, railways, and large areas of hard surfacing.

How do Catch Pits work?

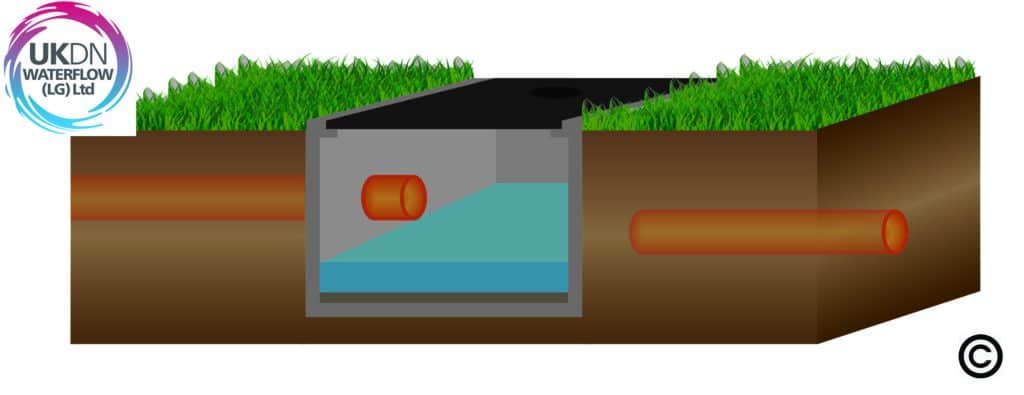

Catch pits have a pipe inlet that is always raised above the floor of the pit. Often, but not always, the outlet pipe is lower than the inlet pipe. As the water flows into the catch pit, silt and debris in it falls to the bottom of the catch pit. The main chamber of the catch pit, where the debris collects, is known as the catch pit sump.

The water then flows out of the catch pit through an outlet pipe. The outlet pipe can be fitted with a baffle that acts as a secondary filter to prevent floating debris from entering the outlet pipe. Catch pits can also be fitted with a grill through which the water drops to catch large debris items before they can fall into the pit.

Because silt and debris build up in catch pits, it is vital that they are cleaned regularly. If this is not done, they can fill up with debris, allowing the material to enter the outlet pipe, or causing a blockage within the catch pit.

The design, size, and location of catch pits is determined by water flow rates, including the maximum flow rate the drainage system is expected to manage, the potential for debris to get into the system, and the maintenance regime that will be put in place.

What are Catch Pits made from?

In the past, catch pits were often brick-lined. Most modern catch puts are made from pre-cast concrete (PCC) or HDPE, high-density polyethylene.

In many cases, PCC catch pits are made in factories in different sizes, with different configurations of inlet and outlet pipes. The right one can then be taken to site and installed at less cost and in less time than building a catch put in situ.

Smaller, track drainage catch pits, used for railway line drainage, are more often made from HDPE. This is, in part, because they are lighter and easier to handle, so more catch pits can be installed during highly controlled track possession times.

Both PCC and HDPE catch pits often combined with catch pit frame systems. These allow the catch pits to be built up to ground level. The catch pit frames are built up in rings until they reach the required level.

The frames are usually made from PCC or glass reinforced plastic (GRP). Catch pit lids, or grills, are then installed on top of the frame to prevent unauthorised access and debris falling into the catch put. These lids can be made from metal, PCC, or GRP.

What can go wrong with Catch Pits?

Catch pits form a vital element of many drainage systems. Common operational and maintenance problems that need to be considered are:

Not enough catch pits – this can be because of inadequate design when the drainage system was installed, or because the circumstances have changed. For example, the nature and flow rates of wastewater have changed, or the drainage system may have been modified.

- Wrong kind of Catch Pit – If the pressure on the wastewater system changes, as described above, the current catch pits may become inadequate for the drainage task expected of them.

- Hidden or buried Catch Pits – Catch Pits can become buried, either through ground works carried out, ground subsidence, or a build-up of debris and silt during localised flooding. In this case, risks of blockages increase, and the catch pits can become overlooked, and not maintained. Drainage system records may be inaccurate or missing, hampering timely maintenance of catch pits, allowing problems to develop.

- Catch Pits not being inspected and cleaned – Catch Pits need to be inspected and cleaned in a timely way, to ensure water can flow freely through them, and that debris is being collected. If these drainage maintenance regimes are not in place, problems can build up over time.

- Catch Pits becoming damaged – This is a particular problem with older catch pits, for example brick lined chambers. Over time, catch pits can be affected by ground movement or structural deterioration.

This can cause them to leak, leading to surrounding ground becoming saturated with water. Or, water can seep into the catch pit, overloading the drainage system. Damaged catch pits can also be affected by root ingress, which can reduce their capacity, cause blockages, cause further damage, and introduce more debris to the drain line.

Damaged catch pits may become unsafe to maintain, due to the risk that they could collapse, or sections could fall, during confined space entry by specialist drainage teams.

Catch Pit inspection and cleaning service

Having a catch pit inspection and cleaning service in place is vital to ensure catch pits, and the wider drainage system they form part of is in good condition and works properly.

This will involve putting in place the appropriate asset condition survey system to monitor catch pits over time, using visual and CCTV drainage surveys. Data can be plotted on highly-accurate drainage maps. Assets can be GPS-located and combined with topographical data. This can be used to design and implement an appropriate catch pit maintenance regime.

Catch pit cleaning and maintenance can be carried out in various ways. They include water jetting and vacuumation, using a jet vac tanker, and digging out catch pits by hand. Where necessary, with larger catch pits, confined space entry may be needed to carry out surveying, cleaning, and other catch pit maintenance tasks.